What Malibu Homeowners Need to Know

Attic insulation requirements in Malibu are shaped by coastal weather, sun exposure, and the need to maintain good indoor air quality in a salt-air environment. Understanding minimum R-values, ventilation needs, fire safety, and air sealing will help ensure your home meets code and performs consistently throughout the year. Whether you are adding material to an existing attic or planning a full upgrade, proper attic insulation is the backbone of energy-efficient comfort in coastal Southern California.

This guide summarizes key requirements and best practices for Malibu homeowners, including code considerations, target R-values, ventilation and moisture control, clearances, and documentation you should maintain for future resale or inspections.

Target R-Values and Code Considerations

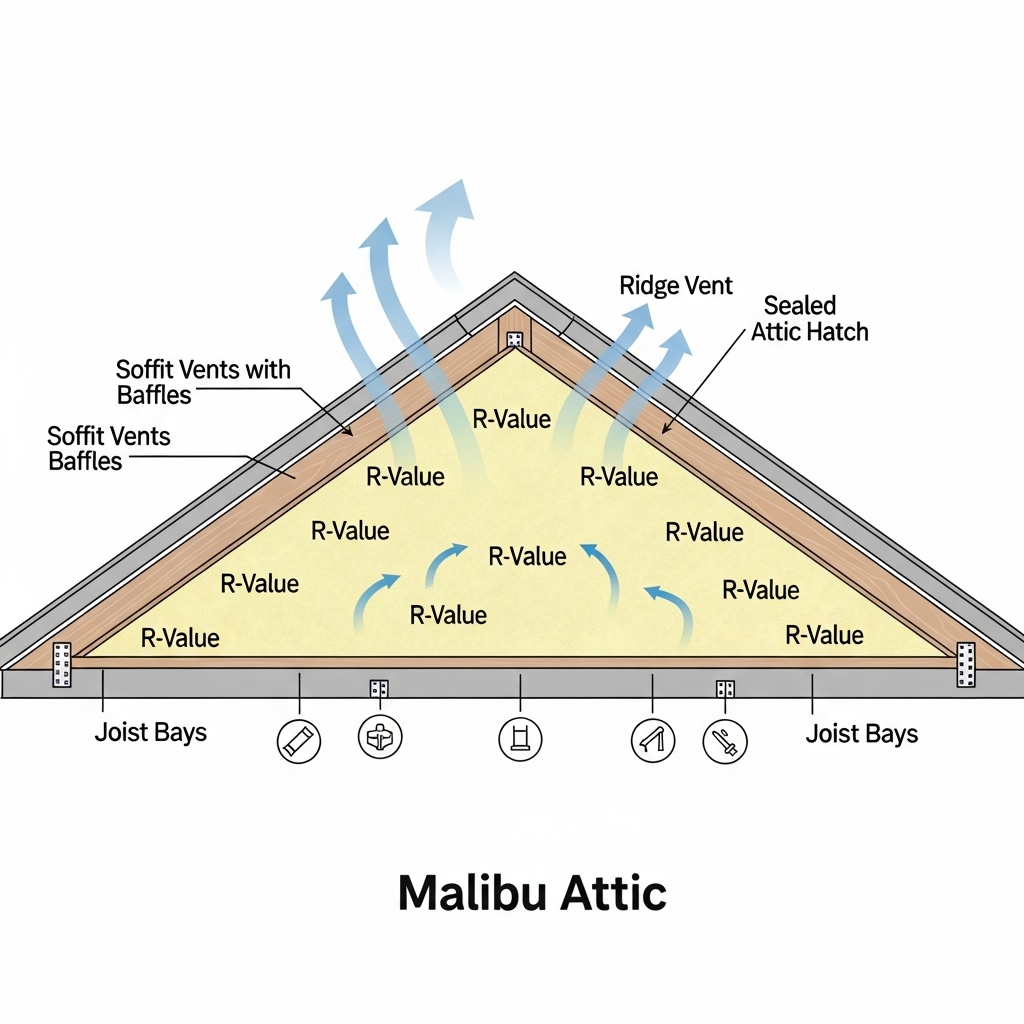

Attic R-values commonly recommended for Malibu’s climate fall in the range of R-38 to R-49 for open attics. If you have cathedral ceilings or limited cavities, the approach can differ, and you may need higher-performance materials to reach the same thermal performance per inch. Always confirm current local code requirements for your zone and roof assembly. R-value targets often consider the balance between summer heat reduction and winter comfort, both important in a coastal climate with wide daily temperature swings.

When adding insulation to an existing attic, you can layer batts or blow loose-fill on top of what’s there, provided the existing material is dry and uncontaminated. Never compress batts to “fit” more insulation into a cavity; compression lowers effective R-value. Use depth markers for loose-fill so you can verify that the installed thickness aligns with the manufacturer’s coverage chart and your code target.

Air Sealing: A Core Requirement

Codes increasingly emphasize air sealing because insulation alone cannot stop air leakage. Seal gaps around top plates, plumbing stacks, electrical penetrations, and chases. Use appropriate sealants and maintain fire-safety clearances at heat-producing devices. Weatherstrip and insulate the attic hatch. Air sealing supports moisture control, enhances comfort, and ensures the insulation layer reaches its full potential.

Ventilation and Moisture Management

Proper attic ventilation helps regulate temperature and moisture. In Malibu, soffit intake paired with ridge or roof vents promotes airflow under the roof deck. Keep soffit vents clear by installing baffles. Do not exhaust bath fans, kitchen fans, or dryers into the attic; vent them outdoors to prevent moisture accumulation and mold risk. Moisture management is a performance and health issue, and it is as critical as thermal resistance in Malibu’s fog-prone periods.

Fire Safety, Clearances, and WUI Awareness

Malibu’s proximity to wildland areas brings heightened attention to fire safety. Follow clearance requirements around flues and chimneys, and use insulation materials with appropriate fire performance. For recessed lights, verify that fixtures are IC-rated if they will be covered by insulation. Maintain required clearances from non-IC-rated fixtures. Review local guidance for ember-resistant venting and screening; intact, code-compliant attic vents help reduce ember intrusion risk during wildfire events.

Working Around Electrical and Mechanical Systems

Label and keep accessible all junction boxes and mechanical service panels. Seal ductwork seams and insulate ducts that run in the attic to minimize heat gain. If the attic houses combustion appliances, ensure adequate combustion air and follow all clearance and safety requirements. Never bury active junction boxes or impede access to shutoffs or service points; inspectors commonly verify access and workmanship in these areas.

Materials and Performance

Fiberglass, cellulose, and mineral wool can all meet Malibu’s performance goals when installed to the correct R-value and with good workmanship. Loose-fill is often favored for uniform coverage in open attics, while batts can be convenient where joist bays are consistent and accessible. Mineral wool offers robust fire resistance and moisture tolerance. Choose materials with proven performance and manufacturer instructions that you can follow precisely. Performance depends as much on installation quality as on material selection.

Documentation and Verification

Good records support resale value and future maintenance. Keep documentation that shows material type, manufacturer, R-value, and installation date. For loose-fill, store the coverage chart and note the installed depth. Take clear photos of depth markers, baffles, and the insulated attic hatch. If you hire a professional, request a summary of the air sealing and insulation work, including any duct sealing or ventilation improvements.

Common Issues That Fail Inspections

– Blocked soffit vents due to missing baffles. – Inadequate insulation depth to meet the required R-value. – Unsealed penetrations and leaky attic hatch assemblies. – Insulation contacting hot flues or covering non-IC-rated lights. – Buried or inaccessible junction boxes and service points. Addressing these ahead of time reduces delays and ensures your attic performs as intended.

Mid-Project Compliance Checks

During installation, pause to confirm that the work meets your plan. Measure insulation depth at multiple points. Verify that ventilation channels remain clear along the eaves. Reinspect air sealing around common leak points like top plates and chases. This midpoint check is also an opportunity to confirm that your selected attic insulation material is being installed without compression and is providing continuous, gap-free coverage.

Quality and Comfort Outcomes

When all requirements are met, you should notice more stable indoor temperatures, quieter rooms, and reduced HVAC cycling. In summer, rooms under the roof will feel less prone to late-afternoon heat spikes. In winter, conditioned air will remain inside longer, improving comfort. Over time, properly installed and documented insulation supports lower energy demand and extends the life of your HVAC system.

Frequently Asked Questions

Q: What R-value is typically required in Malibu? A: Many Malibu attics target R-38 to R-49, but confirm current local code for your exact roof assembly and climate zone.

Q: Do I need a vapor barrier? A: Malibu’s coastal climate generally prioritizes air sealing and ventilation over Class I vapor barriers. Follow manufacturer instructions and code guidance for vapor control layers appropriate to your assembly.

Q: Can I add new insulation over old? A: Yes, as long as the existing insulation is dry, clean, and free of contaminants. Level it, address air leaks, and add new material to reach the target R-value.

Q: How do I keep from blocking soffit vents? A: Install baffles before placing insulation and verify airflow channels are clear during a mid-project check.

Q: What about recessed lighting? A: Only cover IC-rated fixtures with insulation and maintain required clearances for non-IC-rated cans. Consider upgrading to IC-rated sealed fixtures for better performance and safety.

Q: Will inspectors look at my documentation? A: Documentation helps prove compliance and can expedite inspection and resale processes. Keep product labels, coverage charts, and photos of critical details.

Move Forward with Confidence

Meeting insulation requirements in Malibu is about more than hitting a number; it involves airtightness, ventilation, safe clearances, and durable materials working together. If you want a smooth, code-aligned project with reliable long-term comfort, plan carefully, document your work, and don’t hesitate to consult local experts. When you are ready to take the next step, explore your options and schedule professional guidance for high-performance attic insulation in your home.