Why Wall Insulation Mistakes Matter in Malibu

Wall insulation is not just about stuffing cavities with material; it is about building a durable, healthy assembly that manages heat, air, and moisture in a balanced way. In Malibu, California, coastal humidity, salt air, and hillside winds create challenges that magnify the consequences of poor wall detailing. When insulation is installed without considering air sealing, vapor control, and water management, the result can be condensation risks, comfort issues, and premature material wear. Avoiding common mistakes ensures your investment delivers comfort, resilience, and quiet interiors that match Malibu’s relaxed lifestyle.

This guide outlines the most frequent wall insulation pitfalls in Malibu homes, explains why they happen, and shows how to prevent them. If you are planning a remodel or new build, partnering early with a team experienced in insulation installation can help you align product choices and detailing with Malibu’s climate demands.

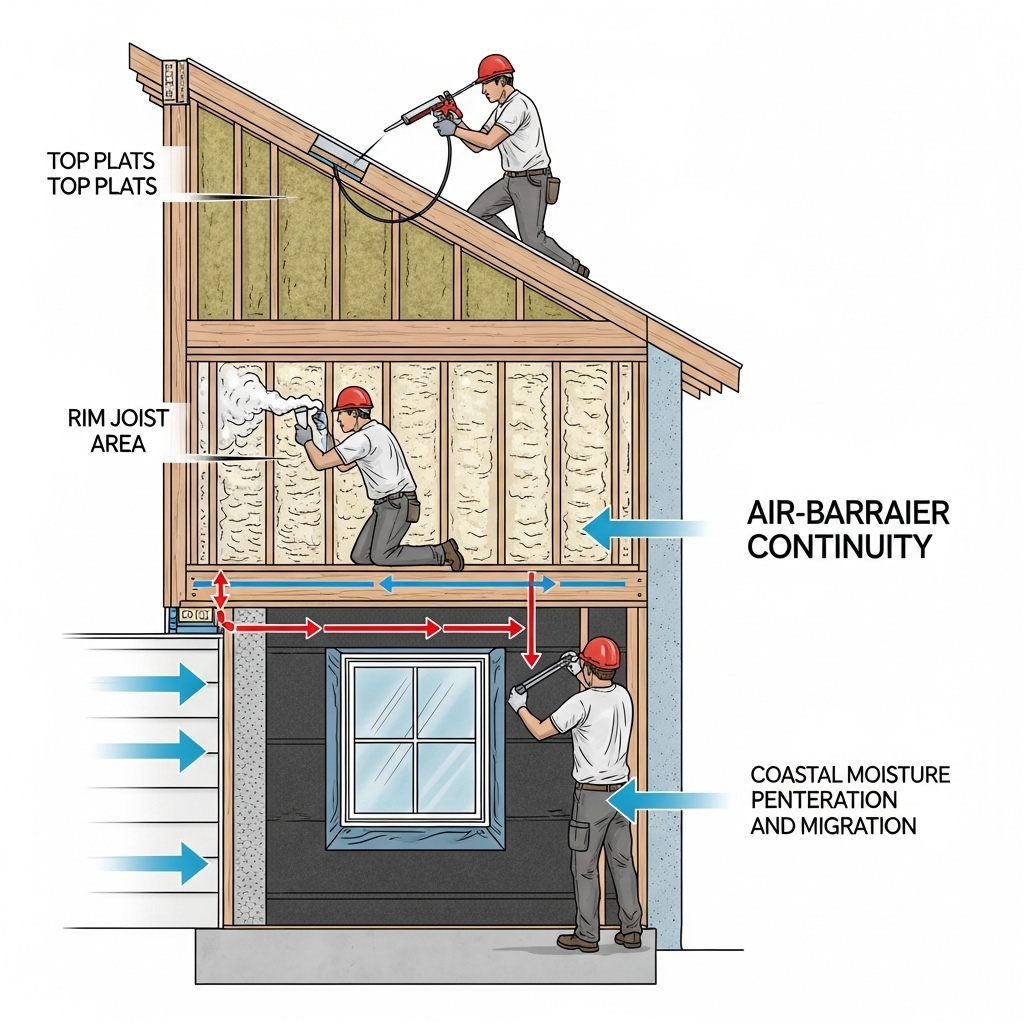

Mistake 1: Ignoring Air Sealing at Transitions

Insulation slows heat, but air sealing stops drafts and moisture-laden air from moving through the assembly. Common leaks occur where walls meet floors and roofs, at window and door perimeters, and at penetrations for wires, pipes, and vents. In Malibu’s marine environment, humid air can be driven by wind into tiny gaps, condensing on cool surfaces. The fix is straightforward but requires diligence: continuous air barriers, sealed top and bottom plates, and careful treatment around openings and mechanical penetrations.

Mistake 2: Overstuffing or Compressing Insulation

Compressing batts or cramming insulation behind pipes and wires reduces thermal performance and can create uneven surfaces that complicate drywall installation. Properly fitted batts or blown-in materials that completely fill the cavity without compression are essential. Where obstructions exist, custom cutting and fitting, or choosing a material that flows around obstacles, maintains performance.

Mistake 3: Misplacing or Misunderstanding Vapor Control

Vapor control is not one-size-fits-all. In Malibu, with moderate temperatures and coastal humidity, the wall assembly must allow for drying while limiting interior moisture from reaching cold exterior layers during certain conditions. The right solution depends on exterior cladding, sheathing type, and interior finishes. Using the wrong vapor retarder, or adding multiple low-permeance layers in a way that traps moisture, can lead to condensation. Align the vapor control strategy with the wall’s drying potential and local code guidance.

Mistake 4: Skipping the Water-Resistive Barrier and Flashing Details

Even the best cavity insulation cannot fix bulk water intrusion. Window flashing, door pans, kick-out flashing, and continuous water-resistive barriers (WRBs) are non-negotiable. In coastal winds, rain can be driven into siding laps and small joints. Flashing details must be layered in a shingle fashion to shed water outward. Poor WRB continuity or reversed laps can allow water to reach the sheathing and insulation, causing damage and reducing thermal efficacy.

Mistake 5: Blocking Ventilation Paths in Vented Claddings

Some claddings perform best with a drained and ventilated air space behind them. If furring strips or rainscreens are part of the design, insulation should not spill into that space or obstruct it. A clear drainage and ventilation gap lets incidental moisture dry, important in Malibu where marine layers can keep exterior surfaces damp. Proper installation preserves this gap and reduces the risk of trapped moisture.

Mistake 6: Neglecting Sound Control Opportunities

Malibu’s soundscape includes ocean surf, canyon winds, and traffic. While exterior noise reduction starts with windows and doors, wall insulation and air sealing also play big roles. Leaving gaps, failing to seal top and bottom plates, or ignoring outlet and switch box sealing lets sound leak in. Choosing materials known for acoustic performance and treating penetrations diligently produces quieter rooms.

Mistake 7: Using the Same Insulation Everywhere

Different parts of a wall assembly face different demands. Rim joists may benefit from denser, moisture-resistant materials. Exterior walls with irregular cavities may be better served by blown-in or spray-applied products. Uniformly applying one product without regard to location-specific needs can underperform. A tailored approach—matching material to task—delivers better results and longevity.

Mistake 8: Overlooking Coastal Corrosion Considerations

Salt air accelerates corrosion on fasteners and metal components. If insulation traps salty moisture against metals, deterioration can speed up. Pay attention to compatible materials, proper air sealing to reduce moist air movement, and diligent water management. In mechanical chases and utility cavities, consider additional protective measures and ensure good access for future maintenance.

Mistake 9: Failing to Coordinate with Mechanical Systems

Walls are part of the whole-home system. If you tighten the envelope with insulation and air sealing, confirm that ventilation and combustion air (if applicable) are addressed. Balanced ventilation improves indoor air quality and comfort. Discuss fresh-air strategies with your contractor, especially in well-sealed Malibu homes.

Mistake 10: Skipping a Thorough Pre-Inspection

Before adding insulation, assess for moisture staining, previous leaks, pest activity, and structural issues. Fix problems first. Insulation can mask symptoms, making problems harder to diagnose later. Document wall conditions with photos, especially before closing cavities, to aid future work and resale confidence.

Best Practices for Malibu Wall Assemblies

1) Treat the wall as a system: control bulk water, air, and vapor in that order. 2) Ensure continuity of control layers at transitions, including foundations, roofs, and openings. 3) Select materials compatible with your cladding and interior finishes. 4) Use backer rods, sealants, gaskets, and tapes that are rated for long-term performance in coastal conditions. 5) Plan penetrations and utility runs to minimize interruptions to the air barrier.

The right detailing often matters more than the brand of insulation. Installer skill shows at the edges—around windows, at base plates, and where different assemblies meet. Malibu’s complex custom homes can feature curves, niches, and multiple cladding types; each transition demands attention.

Spray Foam, Blown-In, and Batts in Walls

Spray foam provides simultaneous insulation and air sealing, helpful in irregular cavities and at rim joists. Open-cell foam offers strong acoustic performance and flexibility; closed-cell adds rigidity and moisture resistance. Blown-in options, such as dense-pack cellulose or fiberglass, fill cavities thoroughly and are excellent for retrofits in existing walls. Batts can work well in standard framing when carefully fitted without compression and when air sealing is done at plates and penetrations.

In Malibu, where sound control and coastal humidity are concerns, hybrid strategies are common: spray foam at critical junctions, dense-pack in standard walls, and carefully detailed batts in simpler areas. The best approach depends on your objectives and the wall’s exterior cladding and interior finish.

Quality Control and Verification

Good installations are verifiable. For dense-pack, crews monitor hose placement, density targets, and coverage to avoid voids. For batts, visual checks confirm full, uncompressed fills. For foam, installers confirm adhesion, consistent texture, and even thickness. Air sealing can be validated with blower door testing and infrared imaging, highlighting any remaining leaks around outlets, baseboards, or window perimeters.

Documentation matters. Photograph concealed areas before drywall, label materials and locations, and keep product data for future reference. These records provide peace of mind and can support resale conversations about the home’s performance features.

Renovation Sequencing and Coordination

Coordinate insulation with window replacement, exterior cladding upgrades, and mechanical work. For example, if new windows are coming, integrate flashing and air barrier details to maintain continuity around the new frames. If electrical or plumbing runs are being modified, complete that work before sealing and insulating. Clear sequencing minimizes rework and protects your investment in wall assemblies.

Working With the Right Team

A seasoned contractor will ask about your goals—quiet bedrooms, even temperatures, moisture control—and then explain how wall details will meet them. They will coordinate with other trades, prepare surfaces, and verify performance as the work proceeds. Midway through planning or during a pre-construction meeting, consider reviewing scope and detailing with a provider experienced in insulation installation, ensuring that Malibu’s coastal realities are reflected in the plan.

Frequently Asked Questions

Q: What insulation type is best for Malibu walls? A: There is no single best type. The optimal choice depends on wall design, cladding, sound goals, and moisture strategy. Many homes use a hybrid approach to match material strengths to specific locations.

Q: Will a tighter wall make my home stuffy? A: A well-sealed wall paired with balanced ventilation makes for a healthier, more comfortable home. The key is designing the ventilation strategy alongside the insulation plan.

Q: Can I insulate over existing materials? A: In some retrofits, dense-pack techniques can fill cavities without full removal. However, if there is moisture damage or contamination, removal and repairs should precede new insulation.

Q: How do windows and doors factor in? A: Window and door perimeters are common air-leak paths. Proper flashing, backer rod, and sealant details, along with insulation that fully fills gaps, are essential to wall performance.

Q: Will wall insulation reduce noise from the Pacific Coast Highway? A: Yes, combined with high-performing windows and meticulous air sealing. Open-cell foam and dense-pack cellulose are particularly effective for sound control.

Take the Next Step

Well-detailed wall insulation elevates Malibu living—quieter rooms, steadier temperatures, and assemblies built to handle marine conditions. If you are planning a remodel or a new build, align materials and methods with your goals and the home’s architecture. When you are ready to translate plans into results with coordinated detailing, connect with trusted experts in insulation installation and move forward with confidence.