Ask five people what duct work should “run per foot,” and you’ll hear five different answers. In a city as varied as Los Angeles, a single metric like linear footage often hides more than it reveals. The length of a run is only one piece of a much larger puzzle that includes fittings, transitions, return strategy, access, testing, and the physics of how your blower moves air. After years of crawling through attics from El Sereno to El Segundo, my take is simple: a whole‑system perspective beats any rule of thumb based on footage. If you’re exploring air duct replacement and wondering how to compare options, here’s why “per foot” thinking can lead you astray—and what to look for instead.

Why linear footage oversimplifies reality

Air doesn’t care about tape measures; it cares about friction, turbulence, and pressure differences. A straight 15‑foot run with gentle curves behaves very differently from a 15‑foot route with two tight elbows, a restrictive boot, and a kink near the register. The second run has a much higher equivalent length, which is what the blower actually “feels.” When a proposal leans on a single per‑foot figure, it can miss these performance‑critical details. The result may be greater noise, uneven temperatures, or a system that struggles on hot Valley afternoons.

Fittings, transitions, and equivalent length

Every elbow, wye, and reducer adds resistance. Smooth transitions and generous radiuses keep friction down, while abrupt turns and undersized fittings pile on losses. Designers calculate equivalent length to account for these effects so that the blower’s available pressure is used wisely. When this isn’t considered, rooms at the ends of long, complex paths often lag in comfort, and the blower has to work harder than it should.

Return air: the unsung hero

Per‑foot thinking often ignores the return. A starved return can sabotage even the most carefully built supply runs by driving static pressure up and choking airflow. Many Los Angeles homes—especially older bungalows and post‑war ranches—benefit from expanded return pathways or additional returns. When the return is right, noise drops and the whole system breathes easier.

Access and the realities of Los Angeles homes

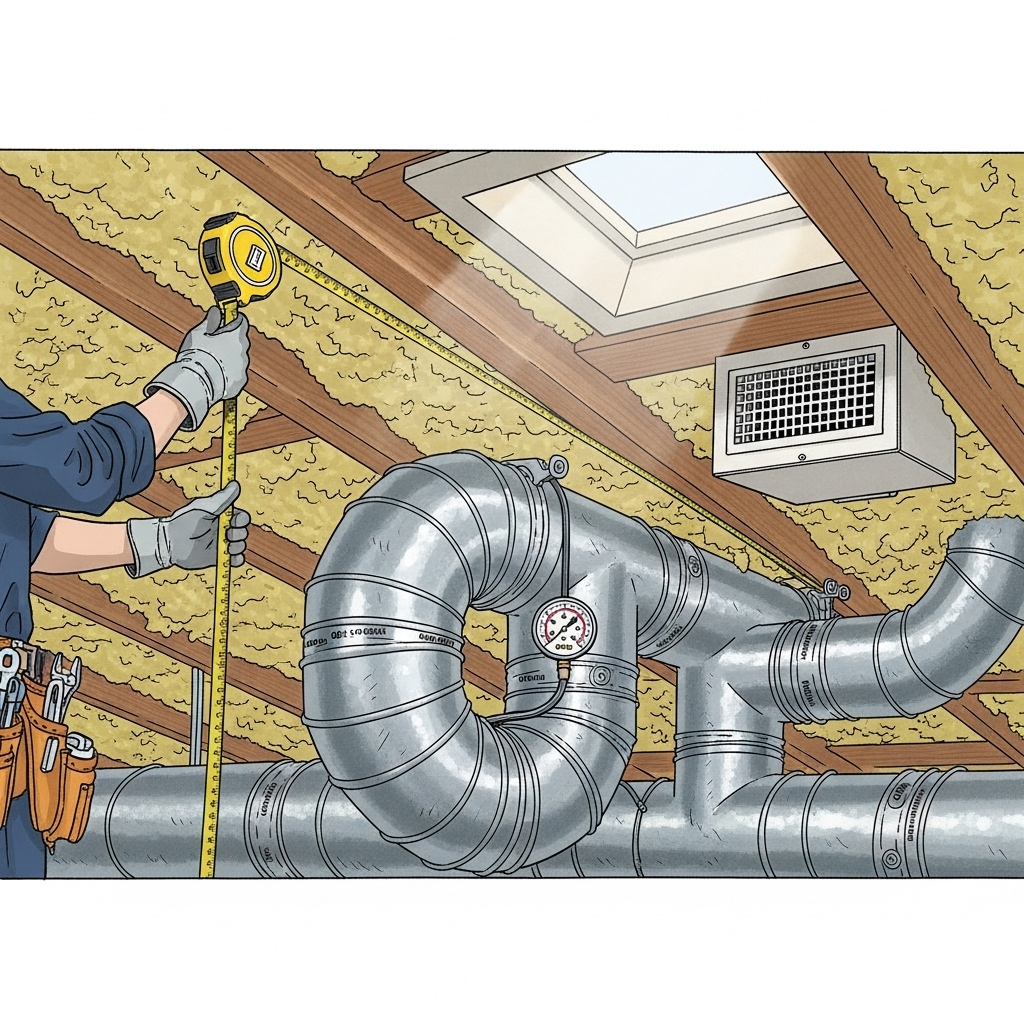

Attic height, truss designs, and existing mechanicals all influence how ducts can be routed and supported. Hillside properties may require careful staging and long material pathways. Condos and townhomes bring HOA rules and limited working hours. Tight crawlspaces demand patience and technique. Linear footage doesn’t capture these realities, yet they determine how tidy the installation is and how long it will last without sagging or kinking.

Materials, insulation, and sealing

Whether the plan uses rigid sections for main trunks or supported flex for branches, the execution matters most. Airtight joints with mastic, listed tapes used correctly, hangers spaced to prevent compression, and insulation chosen for our climate all contribute to performance. In our region’s hot attics, insulation integrity and a tight jacket reduce heat gain and keep supply air closer to the target temperature.

Designing to the blower, not the measuring tape

A good design starts with the equipment’s capacity, the blower’s pressure capability, and the home’s room‑by‑room needs. It accounts for friction rate, equivalent lengths, and diffuser selection. If there are comfort complaints—a warm upstairs bedroom, a loud living room grille, or a home office that always feels off—those become design guides. This approach trades a simplistic per‑foot metric for a plan built around how air actually moves through your home.

Testing and verification

In Los Angeles, Title 24 and HERS verification confirm that leakage is controlled and performance meets current standards. The best teams design with verification in mind, which means choosing fittings and sealing methods that make testing straightforward and results predictable. Documentation at the end gives you confidence that the system you paid for is the system you received.

When footage can be a helpful reference

There is a place for footage—as a rough planning tool to estimate material quantities or to understand how much attic space a new trunk might occupy. But it should never be the sole measure of scope or the primary way to compare proposals. Think of it as one data point among many, subordinate to design and verification.

Comparing proposals the smart way

Instead of asking “what’s the number per foot,” ask how the team will size runs, address the return, seal and support ducts, and verify performance. Ask about static pressure targets and how fittings are selected. A clear, scope‑driven proposal reads like a story: it describes what you have, what you’ll get, and how the crew will manage the space in between—protecting floors, keeping pathways clear, and cleaning up daily.

The middle‑of‑project moment

One of the best times to learn is when new trunks are hung but before insulation wraps everything in a uniform jacket. You can see hangers, radiuses, and transitions. It’s also a chance to confirm that the plan anticipated realities like truss webs or unexpected plumbing lines. If you’re still surveying providers with a focus on air duct replacement, these observations can help you ask better questions and choose a team that thinks beyond footage.

Everyday comfort, not just numbers on paper

The goal isn’t to win a math contest; it’s to enjoy quiet, even comfort in every room. Rooms that settle quickly to the thermostat setting, registers that don’t hiss, and a blower that doesn’t sound like it’s pushing uphill—those are the outcomes of design that respects airflow. When a proposal talks about equivalent length, return strategy, and verification, it’s pointing toward those daily benefits.

FAQ

Is a per‑foot figure ever enough to plan a project?

Not for a real home. Footage can hint at material needs, but performance depends on fittings, turns, return capacity, sealing, and verification. Treat per‑foot figures as background, not the main decision tool.

Why do two homes with similar footage feel so different?

Because their layouts, fittings, and returns differ. Equivalent length and static pressure—not just raw distance—determine how air moves. Small design choices add up to big differences in comfort.

Will new ducts reduce noise?

They can, especially when designs lower static pressure and use smooth transitions and correctly sized registers. Rigid trunks in key stretches and supported flex for branches help tame turbulence and hiss.

How does verification factor into the plan?

Verification confirms leakage control and overall performance. Designing with testing in mind leads to cleaner assemblies, predictable results, and documentation you can keep with your home records.

What about wildfire smoke and outdoor air quality?

In our region, tight returns and smart filtration strategies matter. Sealed, insulated ducts help keep particulates out of the airstream, supporting healthier indoor air during challenging days.

What should I ask when reviewing a proposal?

Ask how the design addresses return capacity, equivalent length, sealing methods, support spacing, and verification. Look for a scope that describes demolition, layout, and final testing, not just a tally of footage.

Ready to move beyond “per foot” thinking?

If you’re aiming for quiet, even comfort, choose a team that leads with design and finishes with verification. Start a conversation with specialists in air duct replacement who understand Los Angeles homes, and turn footage into a complete plan that delivers results you feel every day.